By Aileen Anthony Pics by CellAgritech

Key Takeaways

- Cultivated Protein Is Moving from Concept to Industry The cultivated protein sector has entered a new phase of industrialisation. The focus has shifted from validating the science to scaling production, with proven technologies now being translated into commercial and manufacturing applications across global markets.

- Systemic Alignment Is Essential for Scale Achieving large-scale production requires coordination across regulation, finance, infrastructure, and trade. Regulatory clarity, investment readiness, and interoperable standards will determine the sector’s ability to reach cost competitiveness and long-term sustainability.

- Manufacturing Competitiveness Will Drive the Sector The future of cultivated protein depends on efficient, cost-effective manufacturing systems. Progress will be defined by optimising bioreactors, reducing capital expenditure, managing resources responsibly, and developing adjacent opportunities such as hybrid foods and pet food.

- Consumer Trust Anchors Market Adoption Cultural, religious, and food safety assurance will be decisive in gaining public confidence. Transparent certification frameworks—halal, safety, and environmental—will help ensure acceptance, enabling cultivated protein to integrate smoothly into existing food systems.

- Human Capital and Knowledge Ecosystems Are the Foundation The long-term success of cultivated protein will rest on developing skilled talent, research capabilities, and education-industry partnerships. Building a robust pipeline of expertise across biomanufacturing, regulation, and sustainability will sustain innovation and global competitiveness.

Latest Updates:-

This feature was first published on October 7, 2025. The following is an update on CellAgritech on building the ecosystem through partnerships. On November 19, 2025 CellAgritech together with IMU University, CryoCord Sdn Bhd and Eppendorf, formalised a collaboration for a dedicated lab and GMP-grade facility, purpose-built to translate advanced research into commercial-scale solutions — restoring youthful cell function, decelerating biological ageing and repairing damaged tissues with next-generation regenerative cells. Through its IMUAXL initiative, young innovators work side-by-side with industry and researchers, turning ideas into impact, knowledge into solutions, guided by CellAgritech’s expertise in bioprocessing and large-scale manufacture.

Continues with feature published on October 7, 2025.

From Vision to Implementation

Opening the event on behalf of the Chief Minister, YB Fahmi Zainol, Penang’s State Executive Councillor for Agrotechnology and Food Security highlighted Penang’s ambition to be positioned at the intersection of agricultural innovation and food security policy, a natural staging ground for the sector’s industrial development.

In his keynote, Peter Yu, Programme Director of the APAC Society for Cellular Agriculture, underscored how cultivated meat is moving from concept to reality. Regulatory approvals in markets including Singapore, the United States, and Australia are now establishing precedents.

Yu highlighted cultivated protein’s role in sustainability, resilience, and food security, while cautioning that industry relevance depends on scaling production, reducing costs, and addressing consumer expectations around taste, texture, price, and religious certification.

He emphasised the importance of regulatory coordination across jurisdictions to enable international trade, noting that the APAC-SCA’s regulatory forum is designed to support this objective.

Policy Levers for Growth

Thiruchelvi Rajagobal Reddy, Policy Associate at the Good Food Institute Asia Pacific, reinforced the notion that cultivated meat is not just a scientific advance but a systems-level innovation.

She identified three critical policy pathways:

- Regulatory readiness supported by international standards.

- Public funding and smart capital to bridge long pre-revenue phases and de-risk infrastructure.

- Market and trade development, leveraging Asia’s manufacturing capacity, biomass, and workforce strengths.

Reddy also highlighted the importance of cultural and religious considerations, citing Singapore’s halal framework and Korea’s fatwa permitting cultivated meat. She also mentioned that with the right policies, Malaysia could complement Singapore’s R&D ecosystem by establishing itself as a manufacturing hub.

A Manufacturing-First Approach

Jason Ng, Manufacturing Vice President of Cell AgriTech, anchored the discussion in operational realities. He emphasised that the factory, not the laboratory, will determine the future of cultivated protein.

“If you want to build a product, or need equipment, or want to start without CapEx—we can help,” Ng shared, enabling startups and established players to enter the space without needing to build factories.

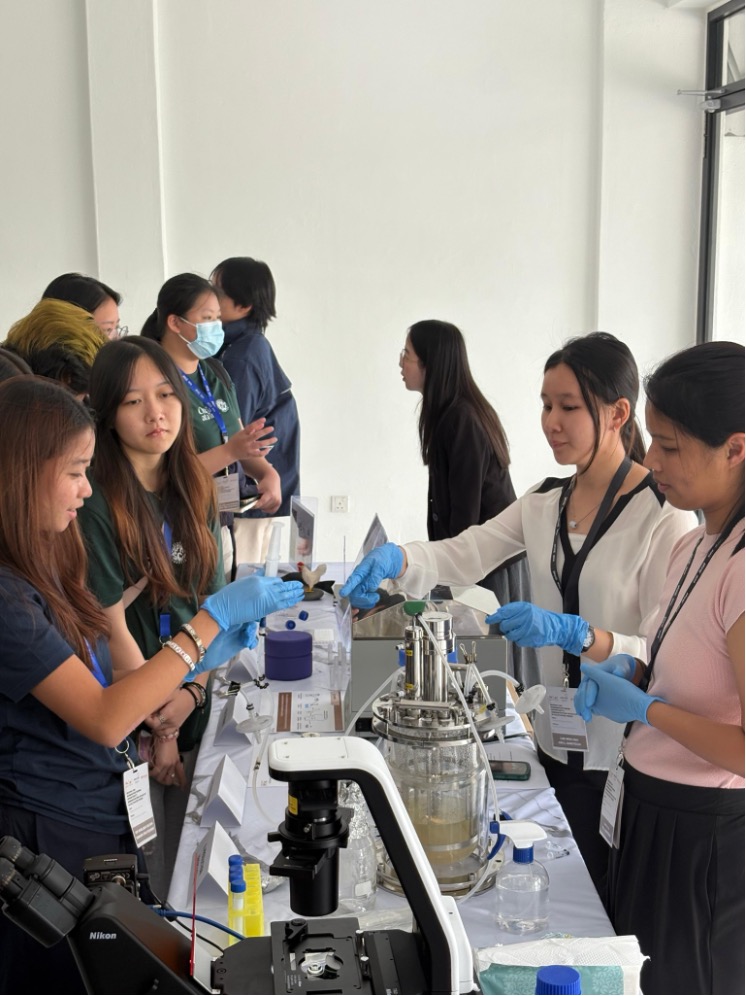

Walking participants through the end-to-end production process from cell banking to bioreactor growth, product formation, and circular use of by-products, Ng underscored the Cell Agirtech’s commitment to cost optimisation, safety, and zero waste.

He also pointed to adjacent opportunities in hybrid foods, pet food, and contract manufacturing, positioning Cell AgriTech as both a producer and enabler of cultivated protein.

Industry Perspectives on Scaling

In a panel moderated by Peter Yu, industry leaders provided frank assessments of scaling challenges:

Avant’s Carrie Chan cited Asia’s strengthening supply chains and pilot-scale progress but warned of the risks of applying pharmaceutical cost structures to food production. Dr. Jay Jee of DaNAgreen described Korea’s proactive use of regulatory sandboxes and innovation in bioreactors, while noting mixed consumer sentiment. Karsten Schellhaus urged startups to adopt cost discipline and food safety standards from the conventional meat sector, while pursuing hybrid products as practical entry points.

The consensus, cultivated seafood and meat will require regulatory clarity, investor confidence, and technical maturity, but the transition may have to be viewed in decades, not years.

The Cost Imperative

A subsequent panel moderated by Jason Ng examined cost competitiveness, widely recognised as the sector’s critical hurdle.

Louis Cheung of JS Biosciences described media as “milk powder for cells” and explained how his company is reducing costs through food-grade ingredients, novel sterilisation methods, and concentrated shipping. GEA’s Claire Han of stressed the importance of fit-for-purpose equipment and continuous processing, warning against unnecessary pharmaceutical standards. She presented innovations such as a compact harvesting unit designed for efficiency. Yuki Hanyu of IntegriCulture highlighted survival strategies including premium positioning, scale-out models, and ecosystem-building to prepare for scale-up.

The discussion concluded that cost reductions will come from systemic alignment across inputs, equipment, and business models, with perfusion technology offering particular promise for productivity gains.

Financing the Transition

Funding was the focus of another panel, which outlined the capital realities of cultivated protein. Moderator Melissa Ong of Founder & Managing Partner, First Frontier Ventures positioned the sector within a trillion-dollar disruption narrative.

Partner, Beyond Impact VC Sagar Tandon, recommended targeting beachhead markets and leveraging Southeast Asia’s food ecosystems instead of replicating Western approaches. Hiroyuki Saito of Ajinomoto illustrated how partnerships in microbial protein can serve as models for scale. Whilst Mahesa Saravanan, Investment Associate, Lever VC, stressed the need for realistic execution, cost parity, and early traction rather than premature global ambitions.

Collectively, the panel underscored the need for blended capital structures—SMEs, corporates, and subsidies—to support the sector, with halal frameworks identified as a unique regional differentiator.

Building Consumer and Cultural Trust

Faith-based assurance was addressed directly by Nurul Hidayah Abubakar of Halal Certification Unit, Majlis Ugama Islam Singapura (MUIS). She explained Singapore’s halal certification framework for cultivated meat, developed over four years and codified in a 2024 fatwa.

Nurul opened with a sobering reminder, by 2050, global food demand will surge by 70%. Climate change, land scarcity, and environmental degradation are pushing the world to find new ways of producing food. “Cultivated meat and seafood grown from animal cells in controlled environments have emerged as one such solution.”

Her remarks highlighted Singapore’s leadership in establishing comprehensive supply chain certification, aligned with international fatwas and guided by the Maqasid al-Shariah principle of preserving life and the environment. The framework demonstrates how innovation and tradition can be integrated.

Ensuring Food Safety

Todd Redwood of Global Managing Director, Consumer, Retail & Food BSI Group addressed another critical factor: food safety. He highlighted the unique risks of cultivated food, including microbial contamination, growth media residues, and mislabelling. He argued for embedding Food Safety Management Systems (FSMS) frameworks such as HACCP, ISO 22000, and Good Cell Culturing Practices into the sector’s foundations.

Redwood emphasised that certification is a strategic necessity to protect consumer trust and enable market entry. “Even a single incident could derail public confidence,” he cautioned, positioning FSMS as essential to risk management and industry credibility.

Regulatory Alignment

A cross-border panel with representatives from Thailand, Japan, and moderated by Calisa Lim, Senior Project Manager, APAC Society for Cellular Agriculture focused on regulatory collaboration.

Peter Yu, Program Director, APAC Society for Cellular Agriculture shared that Singapore’s Novel Food framework is recognised as a benchmark. Thailand’s Dr. Wanarat Sayamol, Pharmacist, Food Division, Thailand Food & Drug Administration briefed on the country’s guidelines on partnerships with industry. Megumi Avigail Yoshitomi, Representative Director, Japan Association for Cellular Agriculture shared on access for imported samples to support education and awareness.

The panel also pointed to cultivated pet food as a near-term commercial opportunity with lower regulatory barriers. The message was clear, regulatory interoperability across Asia-Pacific will accelerate commercialisation and safeguard consumer trust.

Regulation as Strategy

David Ettinger of Keller and Heckman reinforced the view that regulation should be treated as a strategic asset. He advised startups to pursue first filings in open jurisdictions, engage in real-time collaboration via sandbox models, and deploy data-gathering mechanisms such as Freedom of Information Act (FOIA) requests.

For all the science and precision involved in preparing dossiers, Ettinger emphasised one underrated skill: storytelling. “This is data-driven work, yes—but it’s also storytelling. Truthful storytelling,” he clarified. “You need to present data clearly, anticipate follow-up questions, and explain gaps without hiding them.”

Key issues for regulators include allergenicity, media residues, dietary exposure, safety data, and labelling. Ettinger emphasised that regulators are still on their own learning curve, and that companies must invest in clear dossiers, and in-house expertise to build trust.

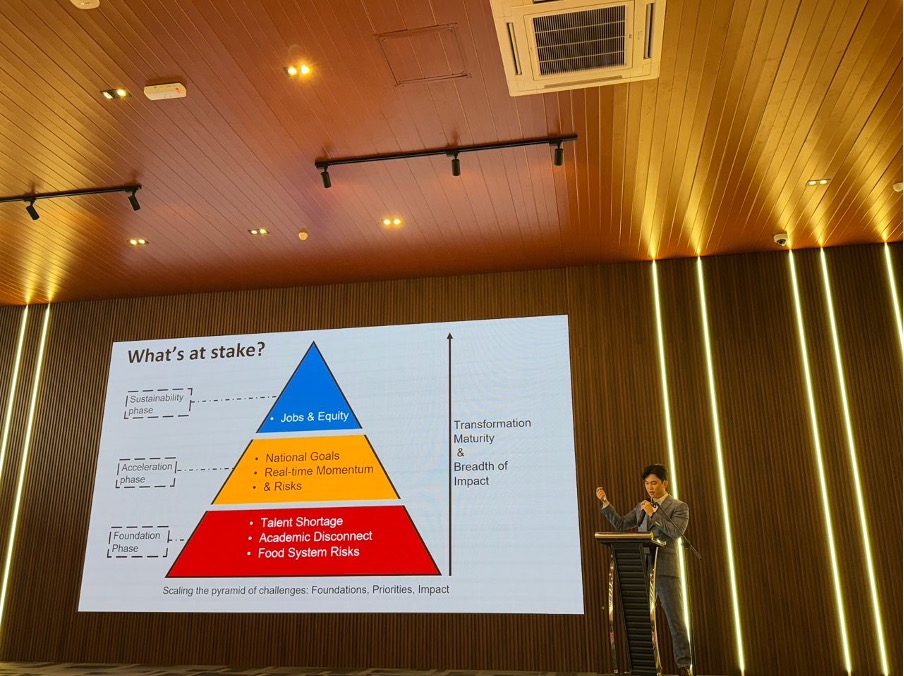

Talent as Infrastructure

Closing on a forward-looking note, Dr James Lim of Temasek Polytechnic stressed that cultivated food’s future rests on people. Temasek’s Future Food Domain provides students with access to bioreactors, bioprinters, and industry projects while fostering partnerships that have expanded sevenfold since 2021.

Lim linked this to Singapore’s “30 by 30” food security target, noting that talent pipelines and industry-academic partnerships are as critical as technological breakthroughs. He called for sustained collaboration across education, policy, and industry to secure long-term leadership.

Outlook

The conference demonstrated that cultivated meat is no longer a speculative technology. It is an emerging sector moving from scientific validation toward industrial scale. The key determinants of success will be:

- Manufacturing competitiveness – lowering CAPEX, OPEX, and cost per kilogram.

- Regulatory clarity – ensuring safety, halal readiness, and interoperability.

- Capital alignment – mobilising diverse funding sources for long-cycle growth.

- Consumer trust – delivering on taste, price, safety, and cultural assurance.

- Talent pipelines – building the human capital to sustain innovation.

As Ng articulated in his opening, the mission is straightforward: “to make cultivated meat and fish affordable and widely available.” Achieving this will require not only scientific excellence but also systemic alignment across supply chains, regulations, finance, and culture.

The sector’s progress will be incremental, and measured not by breakthroughs alone but by disciplined execution. The future of protein is being industrialised; not in isolation, but through coordinated efforts across regions.